Products made from moulded paper pulp are an emerging green and eco-friendly product with an increasingly wide range of applications.

1. Agricultural Product Packaging: Includes natural egg trays/boxes, rice containers, tea boxes, prepared food trays, fruit trays, and meat trays.

Advantages: Using pulp molded egg trays/boxes for egg transportation can reduce the egg breakage rate to less than 2%. Fruit trays can significantly prevent fruit decay and extend shelf life.

2. Food Packaging: Covers fast food packaging (fast food boxes, beverage cups, cup lids, coffee holders, take-out boxes, etc.), supermarket food packaging (vegetables, fruits, meat, seafood, etc.), frozen food packaging (dumplings, buns, steamed buns, tangyuan), dried fruit packaging, biscuit packaging, cheese packaging, etc.

Advantages: Clean, hygienic, convenient, and recyclable.

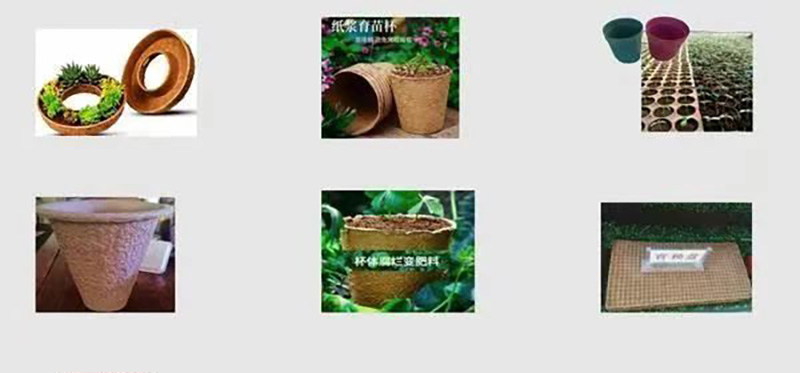

3. Seedling Trays: Includes seedling trays, seedling pots, and functional seedling substrates like desert water retention seedling trays, saline-alkali land seedling trays, balcony seedling substrates, etc.

Advantages: No need for secondary transplantation; after germination, seedlings and trays can be transplanted together. Trays decompose naturally, saving labor and time while maintaining a high survival rate.

4. Industrial Packaging: Includes luxury packaging, cosmetic packaging, electronic product packaging, small household appliance packaging, heavy product packaging, chemical product packaging, logistics packaging, e-commerce cushioning packaging, and fashion fast-moving consumer goods packaging.

Advantages: Replaces plastic with moulded paper pulp. Moulded paper pulp packaging has good plasticity and strong cushioning.

5. Medical Packaging: Includes packaging for disposable medical and hygiene products, disposable surgical supplies, etc.

Advantages: No need for sterilization, labor-saving, and burnable without toxic side effects.

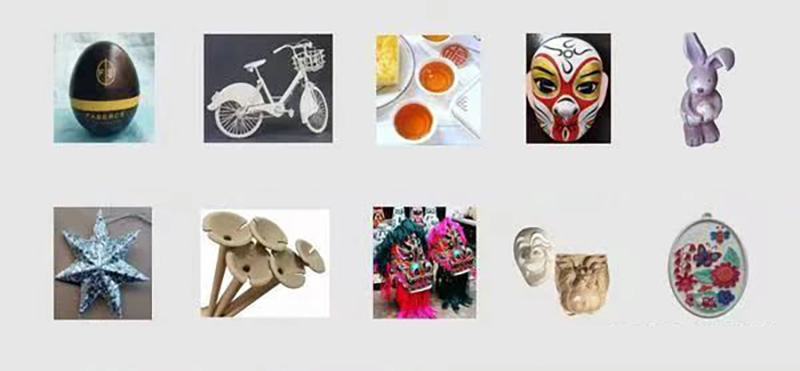

6. Cultural and Creative Products, Educational Supplies, and Tourism Souvenirs.

Advantages: Pulp molding products are highly flexible and can be widely used as substitutes for other materials.

7. Decoration and Travel, Home, and Furniture Products.

Advantages: Convenient for travel, easy to store, and provides good support.

8. Container Packaging Products: Includes packaging for detergents, alcohol, water, yogurt, pharmaceutical bottles, milk powder containers, milk powder scoops, etc.

Advantages: Wide range of applications and low cost.

9. E-commerce, Takeout, and Express Packaging.

Advantages: Biodegradable and environmentally friendly.

10. Other Applications. Includes pet supplies, children’s toys, office supplies, artworks, and paper irrigation pipes.

As an eco-friendly emerging product, pulp molding products are gradually entering the maturity stage of the product life cycle. With the improvement of living standards, enhanced environmental awareness, and continuous technological advancements in pulp molding, the applications of moulded paper pulp products will become increasingly widespread, playing a greater role in global environmental protection and plastic ban initiatives.

Yiwu Jinrui specializes in providing molded pulp for pulp molding factories, such as bleached and natural bamboo pulp, and bagasse pulp.

Home Molded pulp sugar cane pulp moulded paper pulp for packaging 上一页 下一页 Our molded pulp is sugar cane pulp, both bleached and unbleached. It is commonly used for making packages to protecting fragile items during shipping and transportation, as well as for making packages for food products, electronics, and other consumer goods. Molded pulp…

Home The pulp molding packaging market is soaring, eco-friendly food packaging has become the focus As the food takeaway industry develops rapidly, the surge in waste such as disposable plastic tableware and packaging bags has become one of the important sources of global plastic pollution. To meet this challenge, governments and regions worldwide are intensifying…

Home China is one of the central bamboo producing areas in the world. It is a country with the richest bamboo resources, the largest area of bamboo forests, the largest production of bamboo timber, the longest history of cultivation and a high level of management. Bamboo is a valuable resource with a multitude of applications…

Home Is bagasse recyclable? Bagasse is recyclable because it comes from a natural material source. It’s the fibrous part left after extracting juice from sugarcane. This natural fiber can be processed and reused, unlike some synthetic materials that are hard to handle or recycle. It is a natural plant fiber made up mainly of cellulose,…

Home What are the raw materials of paper pulp? Paper pulp materials are the fundamental materials for producing paper, and their quality directly impacts the quality of the final product. These paper pulp materials are mainly divided into two categories: plant fibers and non-plant fibers. Different kinds of raw materials have their unique advantages and…

Home What is bamboo paper pulp used for? Bamboo paper pulp is a type of pulp made from bamboo materials such as Mao bamboo, Nan bamboo, and Ci bamboo. Our factory uses the sulfate method to produce it. Bamboo pulp has medium fiber length and is fine and soft. The pulp sheets are thick and…

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

© 2024 Yiwu Jinrui, All Rights Reserved.