- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8615680886387

Chemical virgin pulp paper buy drying kraft paper pulp board

Chemical virgin pulp paper is produced by the kraft pulping process. Our kraft paper pulp is bamboo pulp, bleached and unbleached.

Our bamboo virgin pulp paper is exclusively derived from 100% bamboo plants cultivated in Sichuan, China.

It can be used in the production of different kinds of paper, kraft papers, and biodegradable tableware products, also can be used in other industries, like construction, and filter paper.

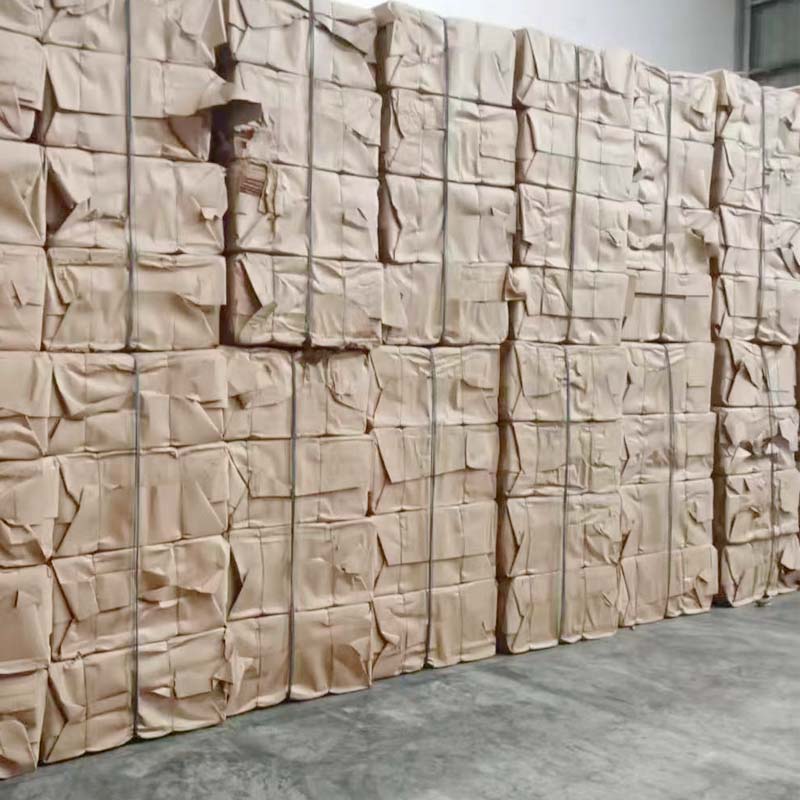

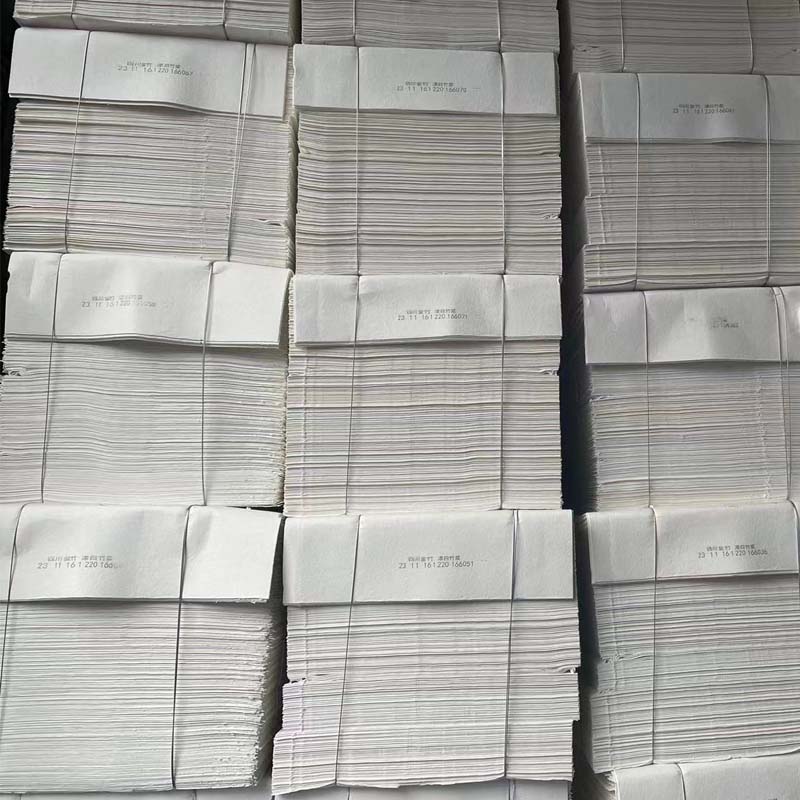

Packing: packed in bale with iron wire.

Size: 840*700*500mm/pack, air dry weight: 250kg/pack

Bale size: 1400*840*2000mm/bale, quantity: 8 packs/bale, air dry weight: 2 tons/bale

Free sample: available.

Product details of virgin pulp paper

The production process of virgin pulp paper typically involves several steps, including harvesting the bamboo, pulping the bamboo fibers, washing and cleaning, drying and baling. Here’s an overview of the bamboo pulp production process:

1. Harvesting: Bamboo plants are harvested when they reach maturity. Sustainable harvesting practices are often employed to ensure minimal impact on the environment and to promote bamboo regeneration.

2. Chipping: After harvesting, the bamboo stems are chipped or shredded into smaller pieces to facilitate the pulping process.

3. Cooking and fiber separation: The bamboo chips are subjected to a pulping process to separate the fibers from the lignin and other components of the bamboo.

4. Bleaching(optional): The pulp undergoes a bleaching process to remove impurities and improve the brightness and whiteness of the pulp.

5. Washing and cleaning: After pulping and bleaching (if applicable), the bamboo pulp is washed and cleaned to remove residual chemicals, lignin, and other impurities. This step is crucial to ensure the quality and purity of the pulp.

6. Drying: The washed bamboo pulp is dried through the use of drying machine. Proper drying is essential to reduce the moisture content of the pulp to the desired level for further processing or storage.

7. Baling: The dried pulp is formed into bales for transportation.

Properties | Unit | Value |

Beating degree | oSR | 45 |

Brightness | % | ≧84 |

Dirt count (0.3-1.0mm2) | mm2 /500g | ≦50 |

Dirt count (1.0-4.0mm2) | mm2 /500g | ≦40 |

Dirt count (≧4.0mm2) | mm2 /500g | None |

Tensile index | N.m/g | ≧50 |

Burst Index | KPa·m2g | ≧4 |

Tear index | mN·m2g | ≧8.5 |

Viscosity | ml/g | ≧800 |

Moisture | % | 15 |

PH | / | 7.15 |

1. Paper production:

Bamboo pulp is utilized in the manufacture of paper products such as tissue paper, toilet paper, printing paper, and packaging materials. Its strong fibers and high cellulose content make it suitable for producing high-quality paper products.

2. Eco-friendly packaging:

Bamboo pulp-based materials are increasingly used in eco-friendly packaging solutions as an alternative to conventional plastics and paper-based packaging. Biodegradable and compostable packaging made from bamboo pulp helps reduce environmental impact and plastic waste.

3. Biodegradable products:

Bamboo pulp can be molded into various biodegradable products such as disposable tableware (plates, bowls, utensils), food packaging, and compostable containers. These products offer a sustainable alternative to single-use plastics and foam-based packaging materials.

4. Construction materials:

Bamboo pulp fibers can be incorporated into composite materials used in construction, such as bamboo fiberboard, panels, and insulation. These materials are lightweight, durable, and have good insulating properties, making them suitable for building and renovation projects.

We can arrange the shipment for customer, by train or by sea. For international shipments, kraft paper pulp can be transported by sea freight using cargo ships. Maritime shipping is suitable for large volumes of pulp and offers cost-effective transportation over long distances.

A 20’GP container has the capacity to carry 20 tons of bamboo pulp.

Can virgin pulp paper be made from bamboo?

Yes, virgin pulp paper can indeed be made from bamboo. Bamboo is a fast-growing grass that can be harvested sustainably, making it an attractive alternative to wood for paper production.

Bamboo pulp shares many characteristics with wood pulp and can be used to produce various types of paper products, including tissue paper, printing paper, and packaging materials.

The process of making virgin pulp paper from bamboo is similar to that of wood pulp, involving mechanical or chemical pulping methods. Mechanical pulping involves physically breaking down the bamboo fibers, while chemical pulping typically involves treating the bamboo with chemicals to dissolve lignin and separate the fibers.

Bamboo pulp is valued for its strength, flexibility, and environmental benefits. Bamboo grows quickly and can be harvested without the need for replanting, making it a highly renewable resource. Additionally, bamboo requires fewer pesticides and fertilizers compared to other crops, further enhancing its sustainability credentials.

Is bamboo virgin pulp paper eco-friendly?

1.Renewability: Bamboo is one of the fastest-growing plants in the world, with some species growing up to 91 cm (36 inches) in 24 hours under ideal conditions. This rapid growth rate makes bamboo highly renewable compared to trees used for wood pulp, which take much longer to mature.

2.Sustainability: Bamboo can be harvested without killing the plant itself, as it regenerates from its roots. Additionally, bamboo can thrive in diverse climates and soil types, requiring minimal water, pesticides, or fertilizers compared to many other crops.

3.Biodegradability: Products made from bamboo virgin pulp paper are biodegradable, meaning they can break down naturally over time, reducing their environmental impact at the end of their lifecycle.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

© 2024 Yiwu Jinrui, All Rights Reserved.