What is bamboo fiber?

China is one of the central bamboo producing areas in the world. It is a country with the richest bamboo resources, the largest area of bamboo forests, the largest production of bamboo timber, the longest history of cultivation and a high level of management.

Bamboo is a valuable resource with a multitude of applications in our daily lives. It can be used in construction, furniture, clothing, and household items, and bamboo shoots can also be consumed. Tens of thousands of people around the world rely on bamboo as a source of income. As an important part of human history and culture, the “Age of Bamboo” will continue to have a lasting impact.

-What is bamboo fiber?

Bamboo fiber is a cellulose fiber extracted from naturally grown bamboo. It has excellent air permeability, instant water absorption, high abrasion resistance and superior dyeing properties. It also has natural antibacterial, anti-mite, anti-odor and anti-ultraviolet functions. Bamboo fiber is an excellent raw material for textile clothing. It has a number of beneficial properties, including antibacterial, moisture absorption and breathability. In fact, it is 3.5 times more breathable than cotton, which is known as a ‘breathing fiber’. At the same time, bamboo fiber products are soft, fluffy and light, with a soft feeling like cotton, a smooth feeling like silk.

Products made of bamboo fiber can be naturally degraded in the soil and decomposed without any pollution to the environment, which is a natural, green and environmentally friendly textile raw material with a broad application prospect in the textile industry.

The chemical composition of bamboo is mainly cellulose, hemicellulose and lignin, the three belong to the same high polysaccharides, the total amount of more than 90% of the dry mass of the fiber, followed by proteins, fats, pectin, tannins, pigments, ash, etc., it is very special that bamboo contains a substance called bamboo quinone, which is antibacterial and anti-mite properties.

-Bamboo Fiber Classification

Bamboo fiber is divided into two categories, namely bamboo raw fiber and chemical bamboo fiber. The latter is further subdivided into bamboo pulp fiber and bamboo charcoal fiber.

Bamboo raw fiber is a natural fiber produced through a combination of physical and chemical methods. It is extracted directly from the bamboo and then spun and woven into clothing. The extraction process is as follows: bamboo material → bamboo chips → steamed bamboo chips → crushed and decomposed → bio-enzymatic degumming → carded fiber → textile fiber. While bamboo raw fiber has superior performance and a simpler preparation process than bamboo pulp fiber, the production process is challenging and requires high-quality control, making it difficult to mass-produce.

Bambuszellstoff fiber is derived from bamboo by crushing and extracting the cellulose into pulp. This pulp is then chemically dissolved to create a viscose-like bamboo pulp. Finally, fibers are spun from this pulp using a wet spinning process, resulting in a chemical fiber.

Bamboo pulp fiber offers a number of advantages, including a lower cost, good moisture absorption and breathability, comfort, better spinning, easy processing and antibacterial mite characteristics. These qualities have made bamboo fiber a popular choice for home textiles, with most products on the market today being made from bamboo pulp fiber.

Bamboo charcoal fiber is a fiber product made from nano-sized bamboo charcoal micro-powder, which is added into viscose spinning liquid through a special process, and then spun out by nearly conventional spinning process. Bamboo charcoal micropowder is made from bamboo by the new calcination technology of pure oxygen, high temperature and nitrogen barrier delay, crushed by airflow and surface modification, the particle size of bamboo charcoal micropowder is not more than 3μm, and the bamboo charcoal micropowder for spinning bamboo charcoal polyester is generally 0.5μm or less. Then the viscose bamboo charcoal fiber was prepared by wet spinning after being evenly dispersed into viscose solution by injection before spinning.

-Bamboo pulp fiber performance characteristics

Due to its special structure and preparation process, bamboo pulp fiber has excellent properties such as moisture retention and breathability, antibacterial and anti-ultraviolet effect.

(1) Good moisture absorption and breathability

Bamboo pulp fiber is a regenerated cellulose fiber, its structure is pore mesh structure, and has more hydrophilic groups, has good moisture absorption, moisture return rate of 13% in the standard state, moisture absorption rate of the fibers in the first.

So, bamboo pulp fiber textiles make people feel particularly cool and comfortable, winter and spring seasons to use both fluffy and comfortable and can eliminate excess heat and moisture.

(2) Good antibacterial properties

Bamboo fiber is naturally antibacterial and does not cause allergic reactions to the skin, because bamboo contains bamboo quinone factors with antibacterial and mite-removing properties.

(3) Deodorising effect

Bamboo pulp fiber has natural anti-odor performance, mainly because the fiber contains chlorophyll and sodium copper chlorophyll and other anti-odor substances, which can remove odor through adsorption of odor and oxidative decomposition pathway.

In addition, bamboo pulp fiber sweating fast, so that the living environment of microorganisms is poor, can also achieve the effect of deodorant.

(4) UV protection

Bamboo pulp fiber contains chlorophyllin copper is safe, excellent ultraviolet absorber, can effectively block ultraviolet radiation on the human body.

(5) Excellent dyeing performance and dyeing rate

Bamboo pulp fiber has a porous mesh structure and low crystallinity, the reactive dyes can be quickly adsorbed on the bamboo pulp fiber, the initial dyeing rate is high, and the dyeing time is short.

-Application

Due to the excellent performance characteristics of bamboo pulp fiber, it is widely used in the textile field.

(1) Knitted fabrics

Bamboo pulp fiber production of knitted fabrics with breathable, moisture absorption, anti-bacterial, deodorant and other advantages, so especially suitable for underwear and socks.

(2) Towel textiles

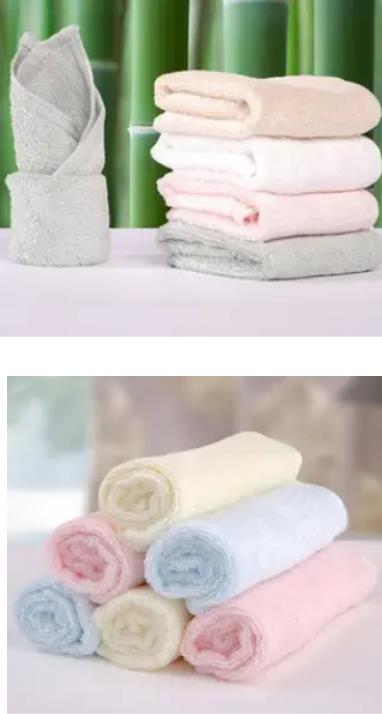

Bamboo pulp fiber towel products have the characteristics of moisture absorption and quick drying, soft and comfortable, the relevant products on the market mainly include bath towels, towels, square towels, etc., which are often woven with cotton yarns as ground and weft yarns and bamboo pulp fiber yarns as terry.

(3) Bedding

Bamboo pulp fiber bedding mainly includes bedding sets and blanket products. Bamboo pulp fiber can be blended with other textile materials. Bamboo pulp fiber blended with linen can optimize the dryness and breathability of bedding; blended with wool to make the products softer and warmer; blended with silk to increase the nobility of the fabric.

(4) Hygiene products

Bamboo pulp fiber products have porous, breathable and anti-bacterial properties, which have good anti-bacterial effect on harmful bacteria, and thus can be widely used in sanitary materials such as sanitary napkins, masks, pads and so on.

For more information about bamboo pulp and bamboo cellulose pulp, welcome to contact with us.