- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8615680886387

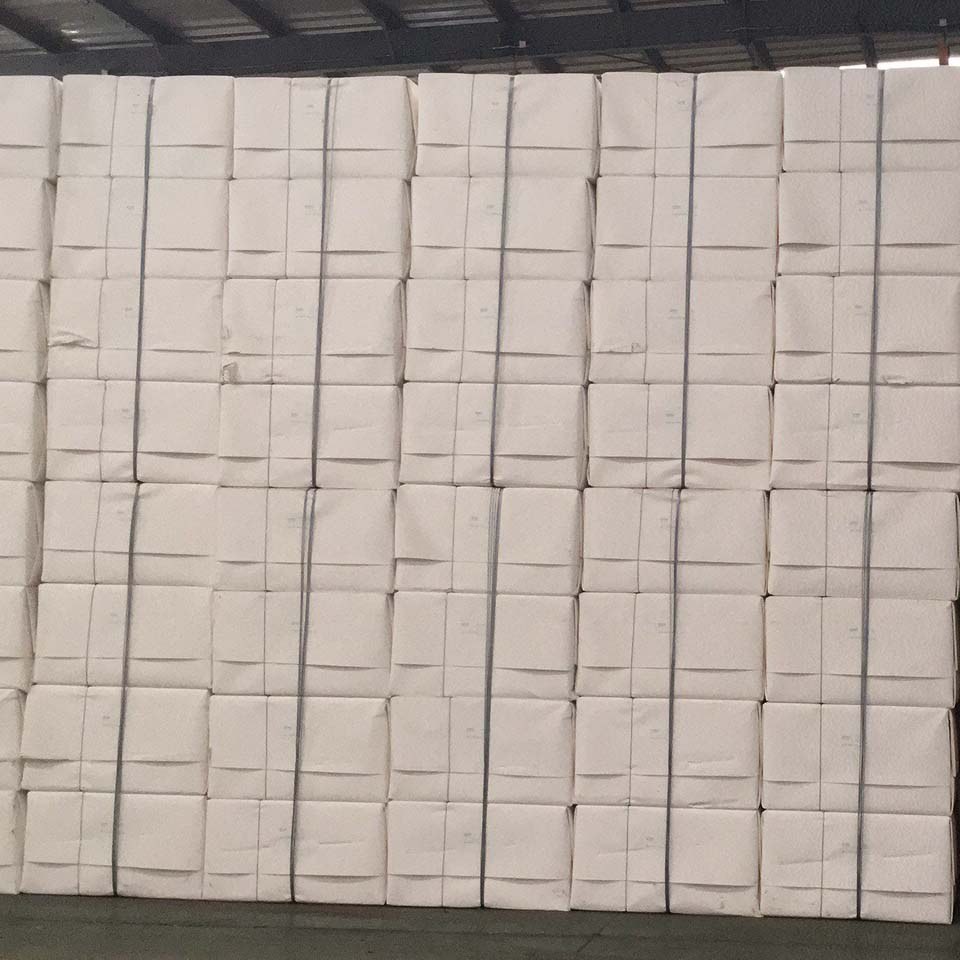

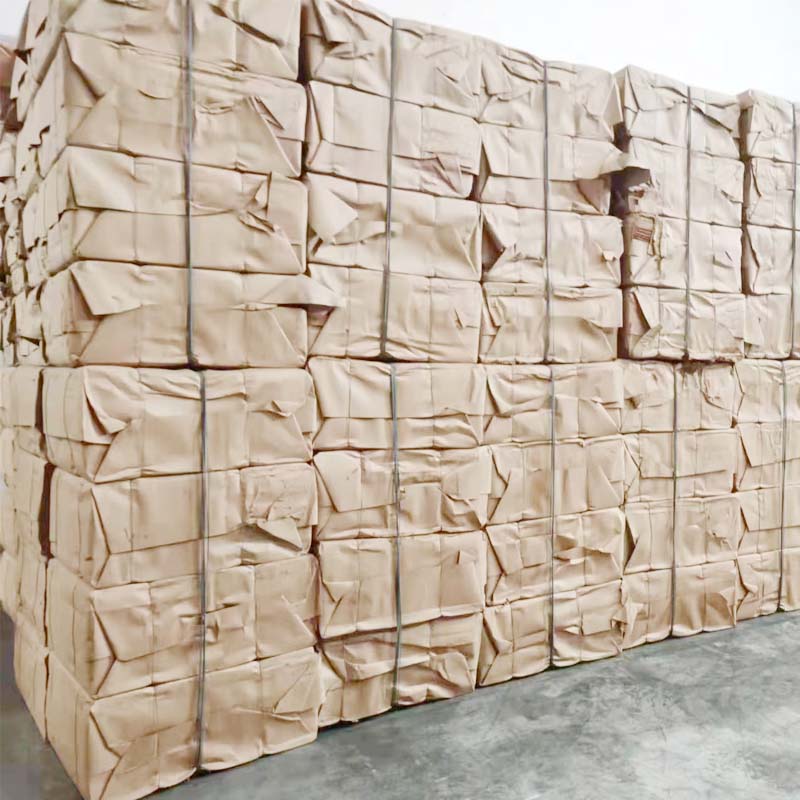

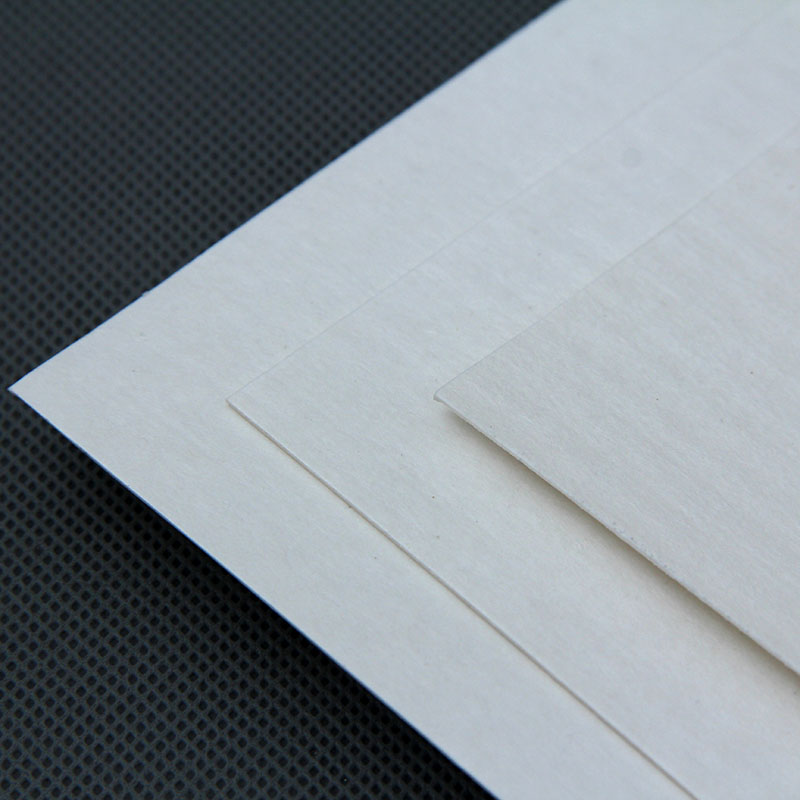

Molded pulp sugar cane pulp moulded paper pulp for packaging

Our molded pulp is sugar cane pulp, both bleached and unbleached. It is commonly used for making packages to protecting fragile items during shipping and transportation, as well as for making packages for food products, electronics, and other consumer goods.

Molded pulp sugar cane pulp is valued for its biodegradability, recyclability, and sustainability, as it is made from renewable materials sugarcane pulp and can often be recycled or composted after use.

Additionally, molded pulp packaging can provide cushioning and protection for products while also reducing the environmental impact compared to traditional packaging materials like plastics.

Our sugar cane pulp is exclusively derived from 100% sugar cane plants cultivated in China.

Bale size: 700*800*600 mm/bale

Air dry weight: 250 kg/bale

Free sample: available.

Technical data of molded pulp

Properties | Unit | Value |

Drainability | oSR | 20-24 |

Brightness | % | ≧80 |

Dirt count (0.3-0.99mm2) | mm2 /500g | ≦35 |

Dirt count (1.0-4.99mm2) | mm2 /500g | ≦5 |

Dirt count (≧5.0mm2) | piece/500g | None |

Tensile index | N.m/g | ≧45 |

Burst Index | KPa·m2g | ≧4.0 |

Tear index | mN·m2g | ≧4.5 |

Viscosity | cm3/g | ≧550 |

Moisture | % | 14±2 |

Fiber wet weight | g | ≧1.7 |

PH |

| 6.5-8.0 |

Properties | Unit | Value |

Drainability | oSR | ≦22 |

Brightness | % | 45±3 |

Dirt count (0.3-5.0mm2) | piece/m2 | ≦40 |

Dirt count (≧5.0mm2) | piece/m2 | None |

Tensile index | N.m/g | ≧45 |

Burst Index | KPa·m2g | ≧4.0 |

Tear index | mN·m2g | ≧4.5 |

Viscosity | cm3/g | ≧550 |

Moisture | % | 14±2 |

Fiber wet weight | g | ≧1.7 |

PH | ≦8.0 |

What is molded pulp used for?

1. Packaging: Sugar cane molded pulp is utilized in the manufacturing of packaging materials. It can be used to produce:

– Corrugated cardboard

– Carton board

– Molded pulp packaging (e.g., egg cartons, trays, and food containers)

– Packaging fillers and cushioning materials

2. Disposable Products: Sugar cane molded pulp is employed in the production of disposable and biodegradable products, offering an eco-friendly alternative to plastics.

– Plates

– Bowls

– Cups

– Food containers

– Cutlery (e.g., forks, knives, spoons)

– Straws

3. Construction and Building Materials: Molded pulp can be used in the manufacturing of construction materials, such as:

– Insulation boards

– Ceiling tiles

– Particle boards

Is sugarcane pulp biodegradable?

Yes, sugarcane bagasse pulp is biodegradable. Bagasse is the fibrous material that remains after sugarcane stalks have been crushed to extract their juice. It is primarily composed of cellulose, hemicellulose, and lignin, which are natural plant fibers.

Due to its composition, bagasse is biodegradable, meaning it can be broken down by microorganisms in the environment over time. When disposed of in appropriate conditions, such as in a composting facility or in soil, bacteria, fungi, and other decomposers will gradually break down the bagasse into simpler organic compounds. This decomposition process contributes to the recycling of nutrients and the regeneration of soil.

The biodegradability of sugarcane bagasse pulp makes it an environmentally friendly material for various applications, including packaging, disposable tableware, and biofuel production. After use, bagasse products can often be composted, returning valuable organic matter to the soil and reducing the burden on landfills.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

© 2024 Yiwu Jinrui, All Rights Reserved.