- Улица Цзяндун, Иу, Чжэцзян, Китай.

- [email protected]

- +8615680886387

Paper Pulp Material Bamboo Pulp with Premium Quality

Bamboo pulp is one of paper pulp material that derived from bamboo plants through a process called pulping.

Производство целлюлозы включает в себя разрушение бамбуковых волокон с получением целлюлозы, которую можно использовать для изготовления различных продуктов.

As a paper pulp material, bamboo pulp can be used in the production of different kinds of paper, and biodegradable tableware products, and also can be used in other industries, like construction, and filter paper.

Bamboo pulp often praised for its sustainability, as bamboo is a fast-growing and renewable resource compared to traditional wood pulp from trees.

- Option: Bleached/Unbleached

- Pulp sheet size: 830*700mm/sheet

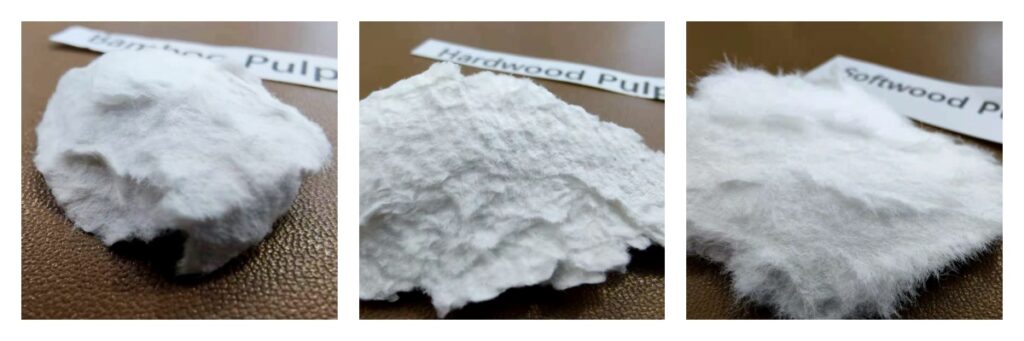

- Fiber length: The length of bamboo pulp fiber is between softwood pulp and hardwood pulp, it is around 1.2 mm to 1.7 mm.

- Delivery: by train or by sea. 20 tons bamboo pulp can be loaded in a 20’ft container.

- Free sample: available

Technical data of paper pulp material

-Bleached

Характеристики |

Единица |

Ценить |

|---|---|---|

|

Дренируемость

|

oSR

|

45

|

|

Яркость

|

%

|

≧84

|

|

Dirt count (0.3-1.0mm2)

|

mm2 /500g

|

≦50

|

|

Dirt count (1.0-4.0mm2)

|

mm2 /500g

|

≦40

|

|

Dirt count (≧4.0mm2)

|

mm2 /500g

|

Никто

|

|

Индекс растяжения

|

Нм/г

|

≧50

|

|

Индекс взрыва

|

KPa·m2g

|

≧4

|

|

Индекс разрыва

|

mN·m2g

|

≧8,5

|

|

Вязкость

|

мл/г

|

≧800

|

|

Влага

|

%

|

15

|

|

PH

|

/

|

7.15

|

|

Air dried Weight

|

ton/bale

|

2

|

|

Bale size

|

мм

|

1400*840*2000mm/bale

|

-Unbleached

Характеристики |

Единица |

Ценить |

|---|---|---|

|

Дренируемость

|

oSR

|

45

|

|

Яркость

|

%

|

34±2

|

|

Dirt count (0.3-1.0mm2)

|

mm2 /500g

|

≦50

|

|

Dirt count (1.0-4.0mm2)

|

mm2 /500g

|

≦40

|

|

Dirt count (≧4.0mm2)

|

mm2 /500g

|

Никто

|

|

Индекс растяжения

|

Нм/г

|

≧50

|

|

Индекс взрыва

|

KPa·m2g

|

≧4

|

|

Индекс разрыва

|

mN·m2g

|

≧10

|

|

Вязкость

|

мл/г

|

≧1000

|

|

Влага

|

%

|

15

|

|

PH

|

/

|

7.15

|

|

Air dried Weight

|

ton/bale

|

2

|

|

Bale size

|

мм

|

1400*840*2000mm/bale

|

Bamboo pulp fiber vs. Wood pulp fiber

What is paper pulp material bamboo pulp used for?

- Papermaking: Bamboo pulp can be used to produce paper products such as toilet paper, tissue paper, printing paper and packaging materials. Its strong fiber and high cellulose content make it suitable for the production of high quality paper products.

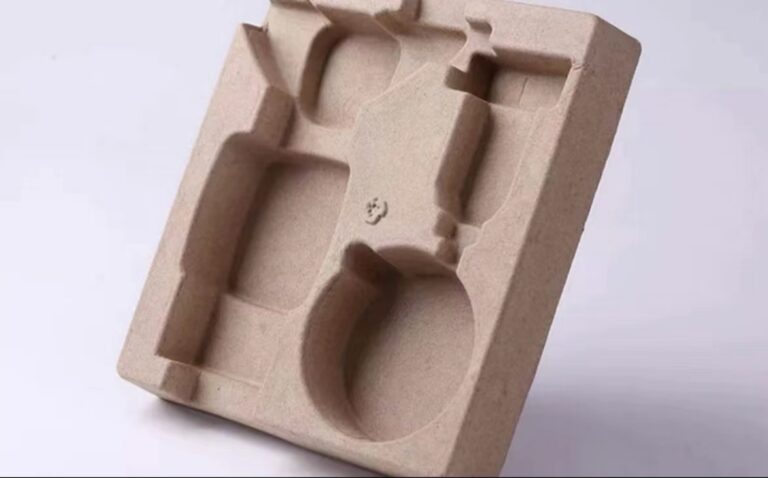

- Eco-friendly packaging: Bamboo pulp-based materials are increasingly being used in eco-friendly packaging solutions as an alternative to traditional plastic and paper-based packaging. Biodegradable and compostable packaging made from bamboo pulp helps reduce environmental impact and plastic waste.

- Biodegradable products: Pulp bamboo can be molded into a variety of biodegradable products such as disposable tableware (plates, bowls, utensils), food packaging, and compostable containers. These products provide sustainable alternatives to disposable plastic and foam-based packaging materials.

- Construction Materials: Bamboo pulp fibers can be blended into composite materials used in construction, such as bamboo fiber boards, panels, and insulation materials. These materials are lightweight, durable and have good insulating properties, making them suitable for construction and renovation projects.

Advantages-Pulp of bamboo

1. Renewable resource: Bamboo is one of the fastest growing plants in the world and is highly renewable. It matures in 3-5 years, whereas trees take decades to mature. This fast growth rate makes pulp bamboo a sustainable alternative to wood pulp.

2. Environmental benefits: Bamboo cultivation requires the least amount of water, pesticides and fertilizers compared to traditional trees used for pulp, reducing the impact on the environment. In addition, bamboo cultivation can help prevent soil erosion and contribute to carbon sequestration.

3. High yield: Bamboo produces more pulp per acre than traditional wood, making it a more efficient use of land.

4. Strength and Durability: Bamboo fibers have inherent strength and durability, making pulp bamboo suitable for a variety of uses, including paper products, textiles and packaging materials.

5. Versatility: Pulp bambooo can be used in a variety of industries other than papermaking, including textiles and construction materials, and even as a substitute for plastics in some cases.

6. Biodegradability: Products made from pulp bamboo are often biodegradable, reducing waste and environmental pollution compared to non-biodegradable alternatives.

7. Antimicrobial properties: Bamboo contains natural antimicrobial properties that can be retained in products made from bamboo pulp, making them suitable for hygiene-related applications.

8. Hypoallergenic: Bamboo fibers are naturally hypoallergenic, making products made from bamboo pulp suitable for people with sensitive skin or allergies.

Bamboo pulp offers a sustainable, versatile and environmentally friendly alternative to traditional wood pulp with a range of benefits across a variety of industries.

Больше продуктов

Yiwu Jinrui является профессиональным поставщиком бумажной промышленности, основанной в 2000 году, от бумажного сырья, бамбуковой целлюлозы, жома, древесной массы до различных видов бумаги.

© 2024 Иу Цзиньруй, все права защищены.