- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8615680886387

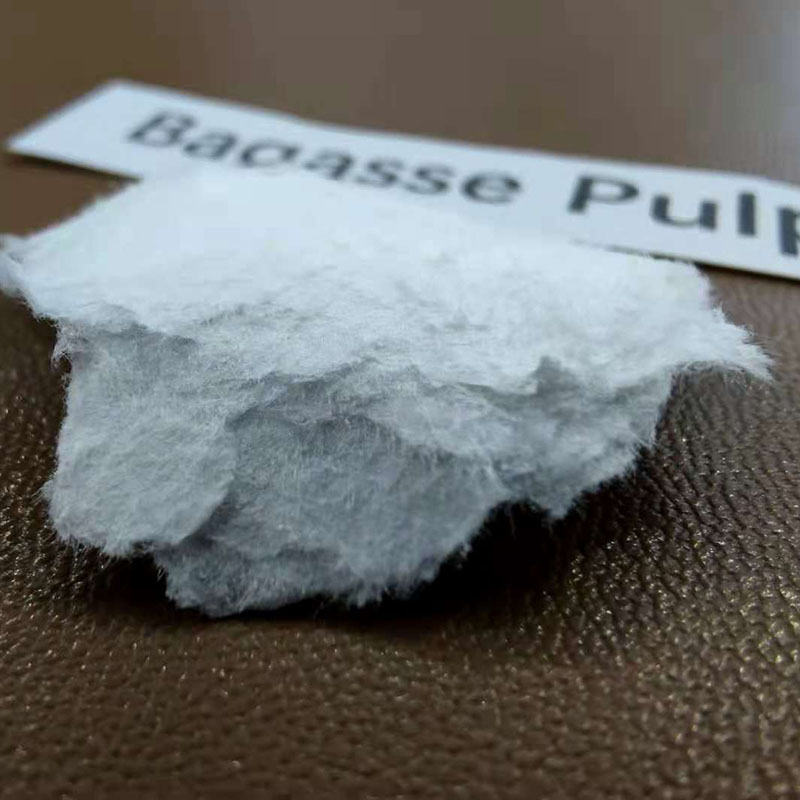

Sugarcane pulp sheet making process

Sugarcane pulp is derived from a renewable resource—sugarcane plants—which can be cultivated and harvested on a regular basis. Its use contributes to the reduction of waste in sugar production processes and supports sustainable practices.

Sugar cane pulp is biodegradable, meaning it can be broken down by microorganisms in the environment over time, reducing its impact on landfills and ecosystems.

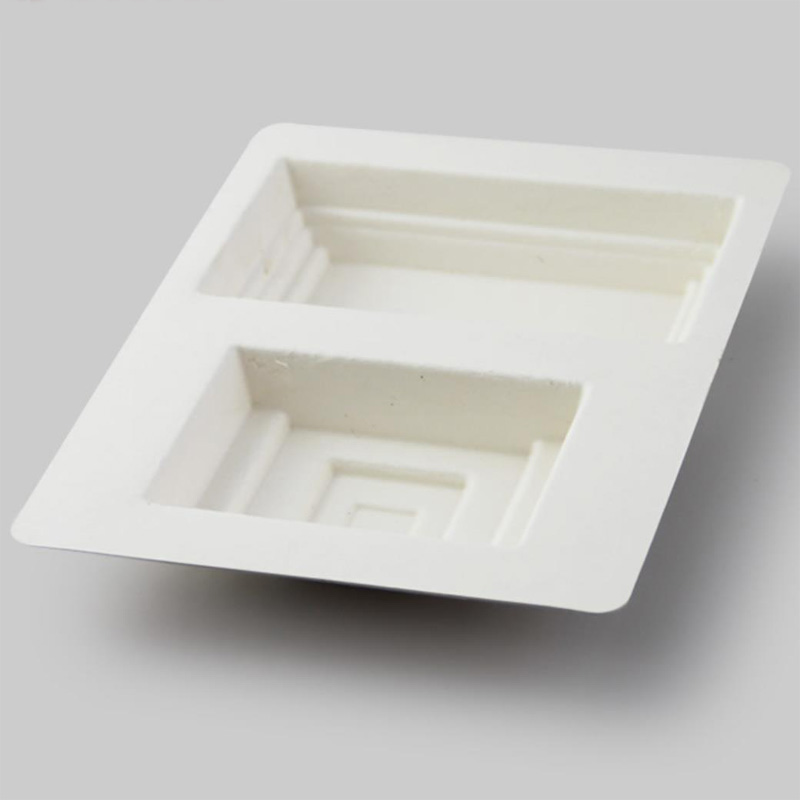

Sugarcane pulp is used to make variety of purposes, including as a biofuel, feedstock for paper and pulp production, and as a raw material for the production of biodegradable products such as disposable tableware and packaging materials.

The length of sugarcane bagasse pulp fiber is shorter compared to bamboo pulp and wood pulp.

Sugarcane pulp making process

1. Collection and Preparation: After sugarcane is processed to extract its juice, the leftover bagasse is collected and transported to a pulp mill. The bagasse may undergo initial cleaning and shredding to remove impurities and break it down into smaller pieces.

2. Pulping: The shredded bagasse is then subjected to a pulping process to separate the cellulose fibers from the lignin and other components of the raw material. We use chemical pulping methods for pulping. Chemical pulping methods are more commonly used for bagasse due to their efficiency in separating fibers.

3. Bleaching: Depending on the desired quality and application of the pulp, it may undergo a bleaching process to whiten the fibers and remove any remaining lignin and impurities.

4. Washing: The pulp is thoroughly washed to remove any residual chemicals and impurities from the bleaching process.

5. Drying: The washed bagasse pulp is dried through the use of drying machine. Proper drying is essential to reduce the moisture content of the pulp to the desired level for further processing or storage.

6. Baling: The dried pulp is formed into bales for transportation.

Technical data

Properties | Unit | Value |

Drainability | oSR | 20-24 |

Brightness | % | ≧80 |

Dirt count (0.3-0.99mm2) | mm2 /500g | ≦35 |

Dirt count (1.0-4.99mm2) | mm2 /500g | ≦5 |

Dirt count (≧5.0mm2) | piece/500g | None |

Tensile index | N.m/g | ≧45 |

Burst Index | KPa·m2g | ≧4.0 |

Tear index | mN·m2g | ≧4.5 |

Viscosity | cm3/g | ≧550 |

Moisture | % | 14±2 |

Fiber wet weight | g | ≧1.7 |

PH | 6.5-8.0 |

Application

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

© 2024 Yiwu Jinrui, All Rights Reserved.