About Us

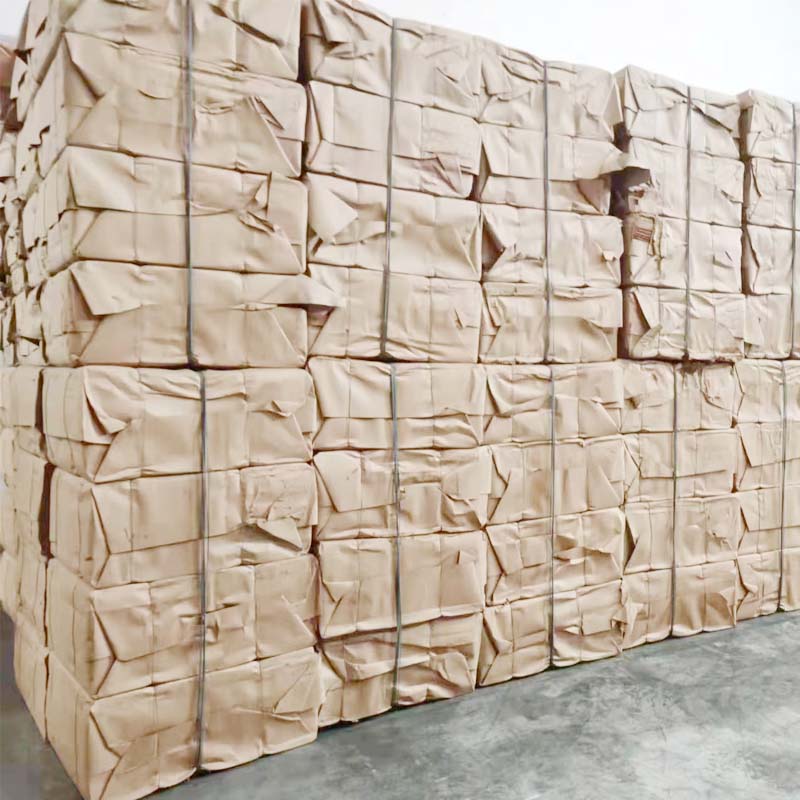

————Paper pulp factory

Using bamboo and sugarcane bagasse as raw materials combines ecological protection, biodegradability, renewability, and food-grade advantages in one.

Papermaking is one of the four great inventions of ancient China. The invention of paper is a great contribution to human civilization. The main raw materials for papermaking are wood, reeds, straw, wheat straw, bamboo, etc., with wood being the most important. We are committed to promoting the use of bamboo fiber and sugarcane fiber instead of wood fiber to reduce deforestation and protect forest resources.

Bamboo and sugarcane bagasse are both high-quality, renewable papermaking resources. China has abundant bamboo and sugarcane resources, which grow every year and can be sustainably utilized. The comprehensive utilization of bamboo and sugarcane bagasse for papermaking is beneficial for resource conservation and ecological protection.

Yiwu Jinrui is a paper pulp factory and supplier with over 20 years of experience specializing in the paper industry, from raw materials paper pulp to various base papers. By promoting the use of biodegradable materials such as bamboo pulp and sugarcane bagasse pulp, Jinrui paper pulp factory could become an important force in driving the world towards a greener and more sustainable direction.

In the future, Jinrui paper pulp factory will continue to uphold its deep love and responsibility for the environment, tirelessly working towards creating a better, greener Earth.

Our Services

All about paper

As a paper pulp factory and paper supplier, we offer a comprehensive range of paper products, spanning from raw materials paper pulps to various base papers.

Quality control

We control every step to provide customers with reliable quality.

Customized service

Except for paper pulp, we offer customization for all product specifications and packaging to meet your unique needs.

Free sample

We offer free samples for customer evaluation.

Follow up

We assign a specialist to follow up the whole process of the order, ensuring the fulfillment of each order with utmost quality and quantity.

Fast Delivery

The paper pulp can be shipped within 3 days after the customer places the order.

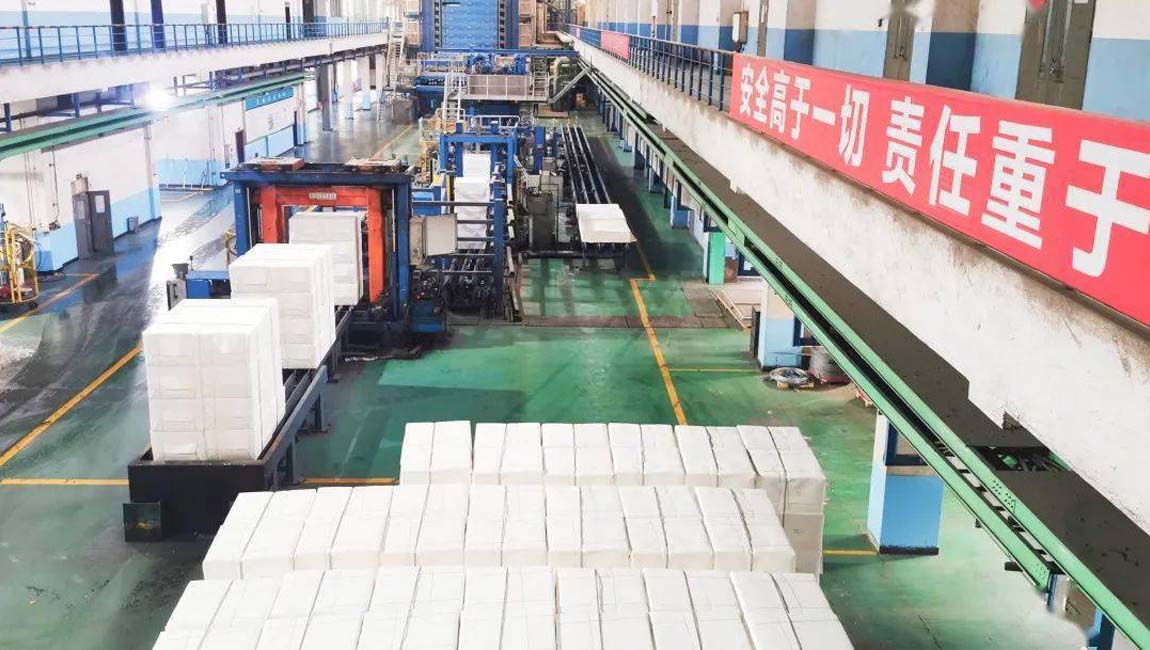

Paper pulp factory production lines

Certificates

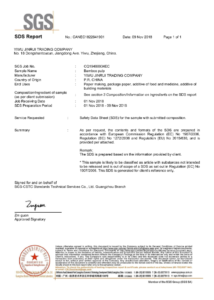

MSDS

Material Safety Data Sheet (MSDS) is a document that lists information relating to occupational safety and health for the use of various substances and products.

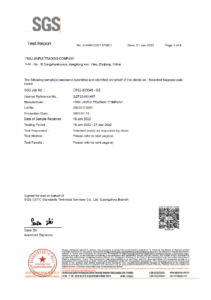

SGS

Our paper pulps have passed elemental analysis, hexavalent chromium, flame retardants, phthalates by SGS.