- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8617380463193

Best unbleached bagasse pulp sugarcane pulp paper supplier for packaging

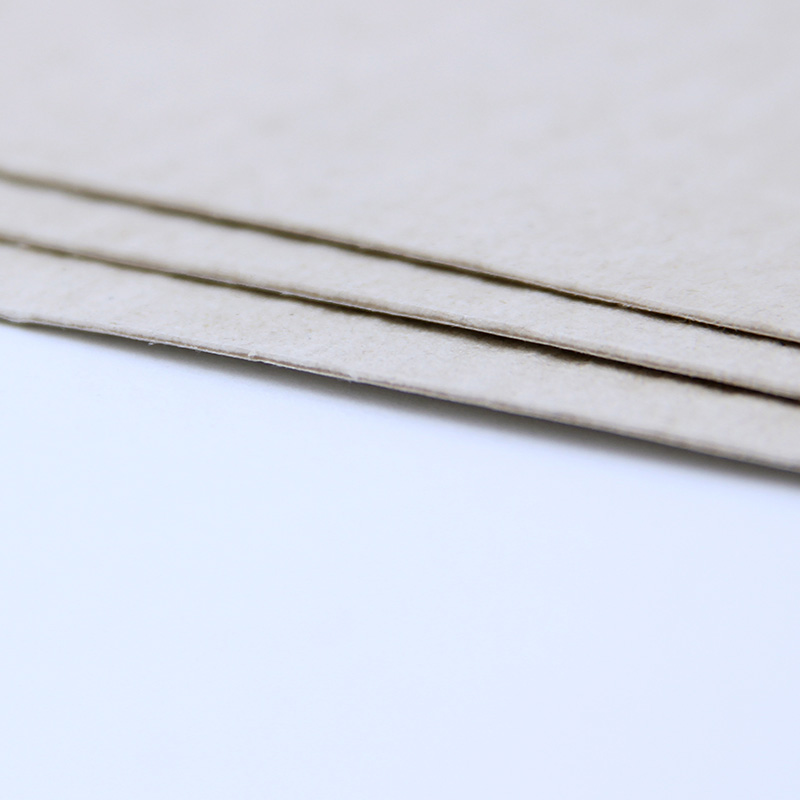

Unbleached bagasse pulp is a type of pulp made from bagasse, which is the fibrous residue left behind after sugarcane or other similar plants are crushed to extract their juice. Bagasse is a byproduct of sugar production, and it has been increasingly utilized as a raw material for papermaking and other applications to reduce waste and environmental impact.

It is processed from bagasse fibers without undergoing a bleaching process and retains its natural color, which is typically a light brown or beige hue.

This type of pulp is often used in the production of environmentally friendly paper products because it reduces the need for chemical bleaching agents, thereby lowering the environmental footprint of the papermaking process. Unbleached bagasse sugarcane pulp is biodegradable and can contribute to sustainable practices in the paper industry.

Product details of unbleached bagasse pulp

Our bagasse sugarcane pulp is exclusively derived from 100% sugar cane plants cultivated in China.

Properties | Unit | Value |

Drainability | oSR | ≦22 |

Brightness | % | 45±3 |

Dirt count (0.3-5.0mm2) | piece/m2 | ≦40 |

Dirt count (≧5.0mm2) | piece/m2 | None |

Tensile index | N.m/g | ≧45 |

Burst Index | KPa·m2g | ≧4.0 |

Tear index | mN·m2g | ≧4.5 |

Viscosity | cm3/g | ≧550 |

Moisture | % | 14±2 |

Fiber wet weight | g | ≧1.7 |

PH |

| ≦8.0 |

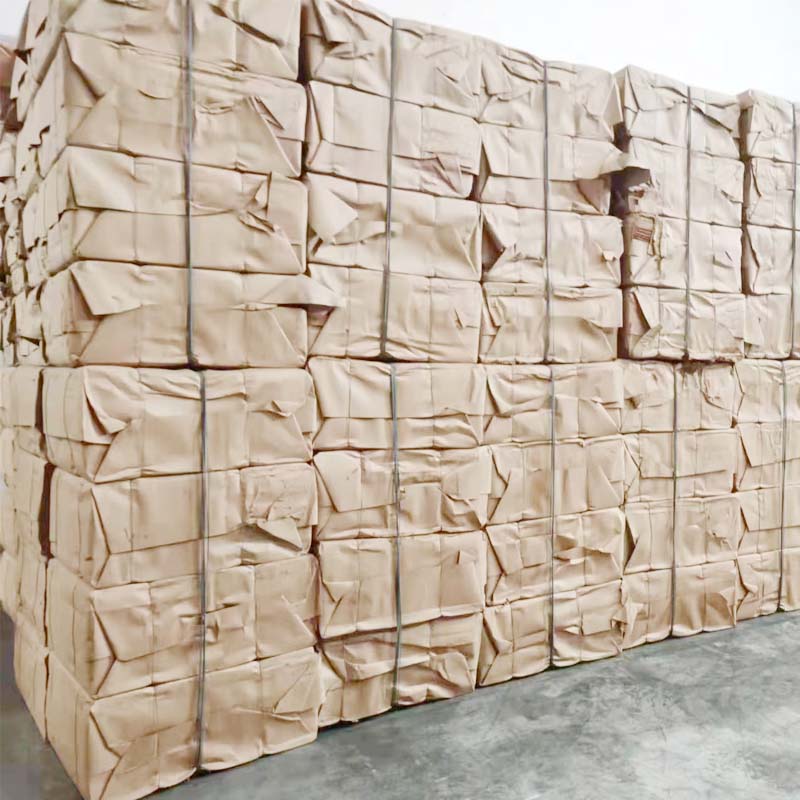

Bale size: 700*800*600 mm/bale

Air dry weight: 250 kg/bale

We offer about 500g-1000g free sample of unbleached sugarcane bagasse pulp for customer to test.

Unbleached bagasse pulp finds applications across various industries where its natural color and properties are advantageous. Some common applications include:

- Packaging Materials: Unbleached bagasse pulp is widely used in the production of eco-friendly packaging materials due to versatility and biodegradability. It is utilized to manufacture:

– Molded pulp packaging, such as trays, containers, and clamshells

– Corrugated cardboard and carton board for boxes and packaging

– Protective packaging materials like cushioning pads and fillers

- Food container: Unbleached bagasse pulp is popular for manufacturing disposable food container, offering a sustainable alternative to conventional plastic or Styrofoam items. These include:

– Plates

– Bowls

– Cups

– Lunch box

– Cutlery (e.g., forks, knives, spoons)

- Paper Products: Unbleached bagasse pulp can be used in the production of various paper products, particularly those where a natural or rustic appearance is desirable. Applications include:

– Kraft paper and cardboard

– Paper bags

– Stationery and notebooks

– Specialty papers with a natural aesthetic, such as artisan papers or textured papers

- Construction and Building Materials: Unbleached bagasse pulp can be incorporated into construction materials for its strength and insulating properties. Common applications include:

– Insulation boards

– Ceiling tiles

– Fiberboard panels and composites

- Biodegradable Products: Unbleached bagasse pulp-based products are preferred for their biodegradability, making them suitable for environmentally conscious consumers and businesses looking to reduce their ecological footprint. They can be used in:

– Single-use disposable items

– Packaging materials

– Compostable products

These applications demonstrate the versatility and eco-friendly nature of unbleached bagasse pulp, offering sustainable alternatives across various industries while reducing environmental impact.

We can arrange the shipment for customer, by train or by sea. For international shipments, sugarcane pulp paper can be transported by sea freight using cargo ships. Maritime shipping is suitable for large volumes of pulp and offers cost-effective transportation over long distances.

A 20’GP container has the capacity to carry 20 tons of bagasse pulp.

The advantage of unbleached bagasse pulp

Unbleached bagasse sugarcan pulp offers several advantages, making it an attractive choice for various applications:

- Renewable Resource: Bagasse, the raw material for bagasse pulp, is a renewable resource derived from sugarcane waste. Utilizing bagasse as a raw material reduces dependence on non-renewable resources like wood pulp and helps mitigate deforestation. It also promotes more sustainable agricultural practices by finding value in sugarcane byproducts that would otherwise be discarded.

- Cost-Effectiveness: Producing unbleached sugarcane pulp typically requires less processing compared to bleached pulp, resulting in lower production costs. This cost-effectiveness can make unbleached pulp a more affordable option for manufacturers, leading to potential cost savings and improved competitiveness in the market.

- Natural Appearance: Unbleached sugar cane pulp retains its natural color and appearance, which can be desirable for certain applications where a rustic or eco-friendly aesthetic is preferred. The natural appearance of unbleached pulp adds character and uniqueness to paper and packaging products, distinguishing them from those made with bleached pulp.

- Health and Safety: Unbleached sugarcane pulp eliminates concerns about potential exposure to residual chemicals found in bleached pulp products. This can be particularly important for applications involving direct contact with food or skin, where consumers may prefer products made from natural and chemical-free materials.

- Versatility: Bagasse pulp can be used to produce a wide range of products, including paper, packaging materials, disposable products, construction materials, and more. Its versatility makes it suitable for various industries and applications.

- Biodegradability: Unbleached bagasse pulp is biodegradable and compostable, meaning it can break down naturally over time without leaving harmful residues. This makes it an environmentally friendly choice for disposable items and packaging materials, contributing to waste reduction and resource conservation.

- Eco-Friendly Brand Image: Companies that utilize unbleached bagasse sugarcane pulp in their products can benefit from a positive eco-friendly brand image, appealing to environmentally conscious consumers and meeting sustainability goals.

Unbleached bagasse pulp provides a sustainable, cost-effective, and environmentally friendly alternative to bleached pulp, offering numerous advantages for manufacturers, consumers, and the planet.

How to make sugarcane bagasse pulp?

The production process of unbleached bagasse sugarcan pulp typically involves several steps:

1.Collection and Preparation: After sugarcane is processed to extract its juice, the leftover bagasse is collected and transported to a pulp mill. The bagasse may undergo initial cleaning and shredding to remove impurities and break it down into smaller pieces.

2. Pulping: The shredded bagasse is then subjected to a pulping process to separate the cellulose fibers from the lignin and other components of the raw material. We use chemical pulping methods for pulping. Chemical pulping methods are more commonly used for bagasse due to their efficiency in separating fibers.

3. Washing: The pulp is thoroughly washed to remove any residual chemicals and impurities from the bleaching process.

4. Drying: The washed bagasse pulp is dried through the use of drying machine. Proper drying is essential to reduce the moisture content of the pulp to the desired level for further processing or storage.

5. Baling: The dried pulp is formed into bales for transportation.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

Jinrui All Rights Reserved.