- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8617380463193

Cellulose wood pulp supplier unbleached softwood pulp price

Cellulose wood pulp refers to pulp derived from trees, with softwood pulp being extracted from softwood trees, primarily coniferous trees such as pine, spruce, fir, and hemlock. Softwood trees have longer, straighter fibers compared to hardwood trees, which typically have shorter and more irregular fibers.

Softwood pulp is known for its strength, long fibers, and high cellulose content, making it particularly suitable for applications where strength and durability are important, such as in the production of packaging materials, paperboard, and specialty papers like high-quality printing papers.

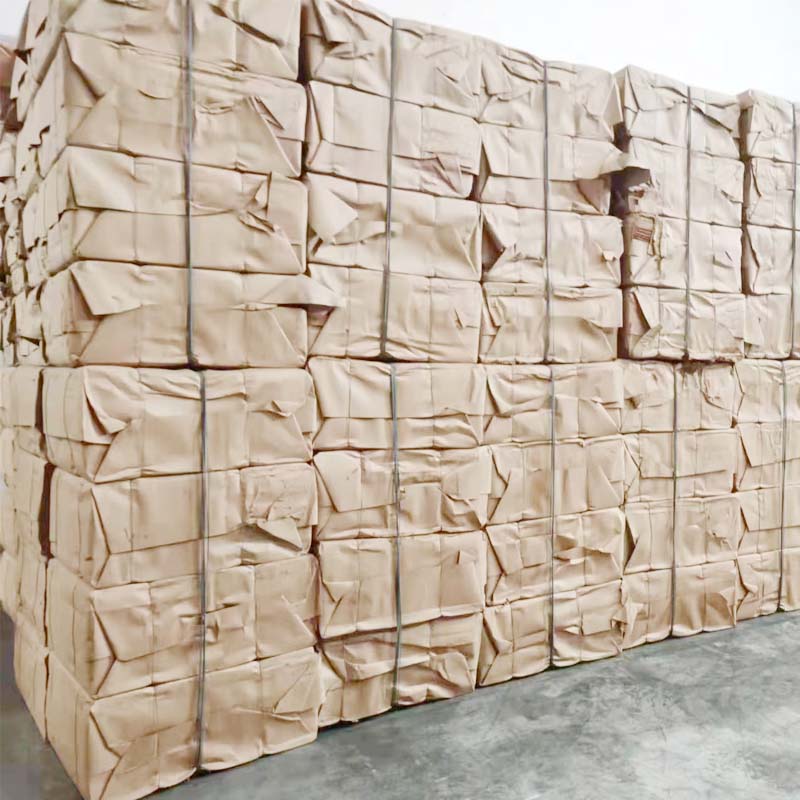

The cellulose wood pulp is in sheet form. It is packed in bale with iron wire.

Packing: 840*700*520mm/pack, 1400*840*1800mm/bale, around 1.98 tons/ bale.

Free sample: Available.

Technical data sheet of cellulose wood pulp

Properties | Unit | Value |

Drainability | oSR | 35 |

Brightness | % | ≧87 |

Dirt count (0.05-5.0mm2) | mm2 /kg | ≦50 |

Tensile index | N.m/g | ≧70 |

Burst Index | KPa·m2g | ≧5.0 |

Tear index | mN·m2g | ≧8 |

Moisture | % | 10±2 |

Ash content | % | ≦0.5 |

What are the softwoods used in paper industry?

In the paper industry, several types of wood for paper making. Some of the main paper pulp tree species utilized include:

1. Pine: Pine trees are widely used in the paper industry due to their abundance and favorable fiber characteristics. Varieties such as Scots pine, Eastern white pine, and Southern yellow pine are commonly utilized.

2. Spruce: Spruce trees, particularly species like Norway spruce and Sitka spruce, are valued for their long, slender fibers, which contribute to the strength and smoothness of paper products.

3. Fir: Fir trees, including species like Douglas fir and balsam fir, are another important source of softwood pulp. They provide fibers with good strength properties, suitable for various paper grades.

4. Hemlock: Hemlock trees, such as Eastern hemlock and Western hemlock, are also used in the paper industry. Hemlock fibers are known for their strength and versatility in papermaking.

These softwood species are processed into pulp and the resulting pulp is utilized in the production of a wide range of paper and paperboard products, including newsprint, packaging materials, printing papers, and specialty papers.

Our softwood pulp is made from southern pine.

What is cellulose wood pulp used for?

The cellulose wood pulp is a versatile material with a wide range of applications across various industries. Some common uses of cellulose wood pulp include:

- Paper Production: Wood pulp is the primary raw material for producing paper and paper-based products, including:

– Printing and Writing Papers: Newspapers, books, magazines, office papers, and other printed materials.

– Packaging Materials: Cardboard, paperboard, corrugated board, and other packaging materials used for boxes, cartons, and containers.

– Specialty Papers: Tissue paper, filter paper, label stock, and other specialty papers with specific properties such as absorbency, strength, or surface smoothness.

- Construction Materials: Wood pulp can be processed into engineered wood products used in construction, including:

– Fiberboard and Particleboard: Interior and furniture-grade panels made from compressed wood fibers bonded with adhesives for furniture, cabinets, and building materials.

– Insulation: Thermal and acoustic insulation materials made from wood fibers for buildings and homes.

- Filters and Specialty Applications*: Wood pulp fibers are utilized in various specialty applications, such as:

– Air and Liquid Filtration: Filters for air purification, water treatment, and industrial processes due to their high surface area and ability to capture particles.

– Battery Separators: Separators in lead-acid batteries to prevent short circuits.

– Food Packaging: Packaging materials with specific barrier properties for food packaging applications.

- Biodegradable Products: Wood pulp is a renewable and biodegradable material, making it suitable for environmentally friendly products and packaging solutions.

Sulfate wood pulp plays a crucial role in numerous industries, contributing to the production of a wide range of everyday products and materials.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

Jinrui All Rights Reserved.