- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8617380463193

Bamboo paper pulp uses for packing paper manufacturer

Bamboo paper pulp, also known as bamboo fiber or bamboo cellulose, is a material derived from bamboo plants that is used to produce a variety of products, including paper, textiles, and some types of biodegradable products.

To create bamboo paper pulp, bamboo stalks are harvested and processed to extract the cellulose fibers. These fibers are then treated and spun into threads or dissolved in a solution to produce pulp for papermaking or other applications.

Bamboo pulp is favored for its sustainability as bamboo is a fast-growing and renewable resource. It’s also known for its softness, absorbency, and antibacterial properties, making it a popular choice for eco-friendly paper, packaging and biodegradable products.

Product details of bamboo paper pulp

The bamboo paper pulp is exclusively derived from 100% bamboo plants cultivated in Sichuan, China.

Properties | Unit | Value |

Beating degree | oSR | 45 |

Brightness | % | ≧84 |

Dirt count (0.3-1.0mm2) | mm2 /500g | ≦50 |

Dirt count (1.0-4.0mm2) | mm2 /500g | ≦40 |

Dirt count (≧4.0mm2) | mm2 /500g | None |

Tensile index | N.m/g | ≧50 |

Burst Index | KPa·m2g | ≧4 |

Tear index | mN·m2g | ≧8.5 |

Viscosity | ml/g | ≧800 |

Moisture | % | 15 |

PH | / | 7.15 |

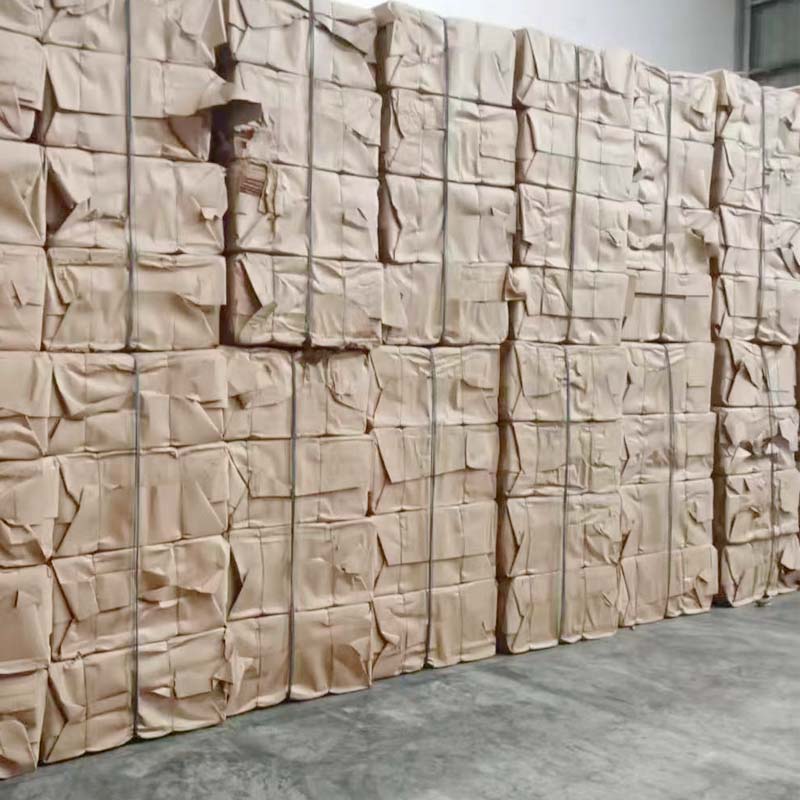

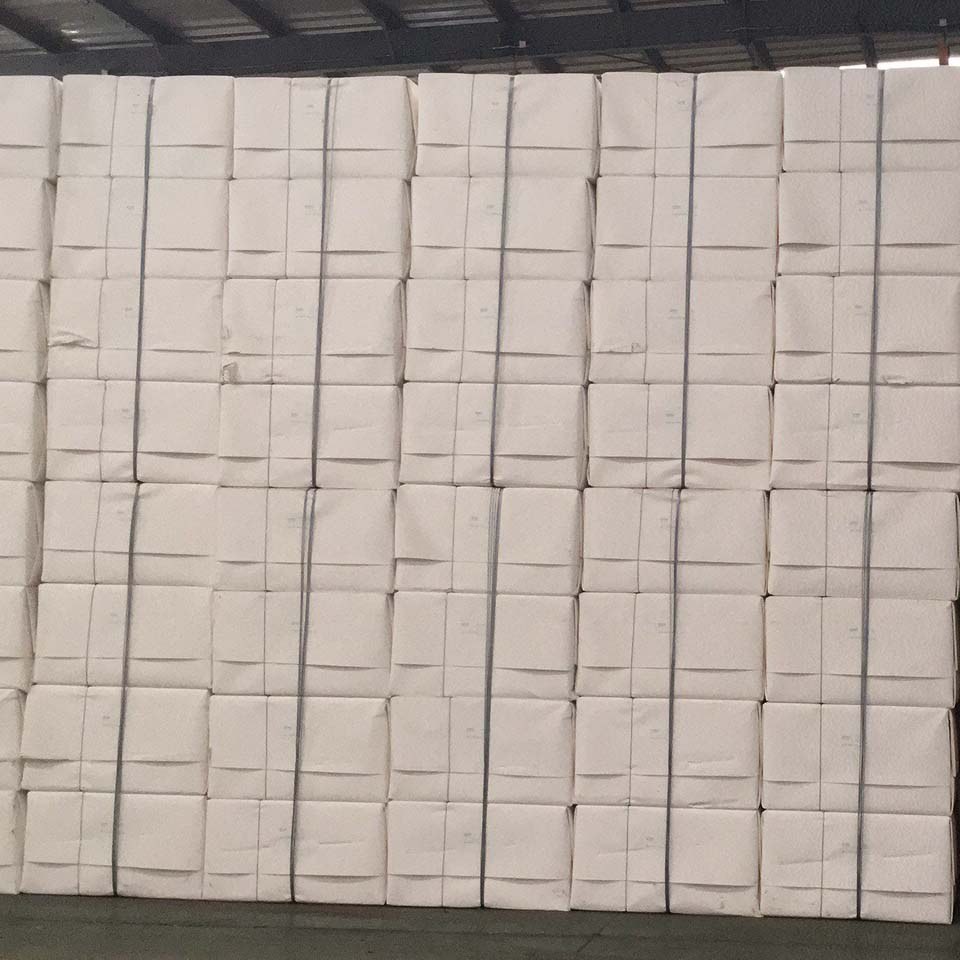

Bamboo paper pulp is in sheet form. It is packed in bale with iron wire.

Size: 840*700*500mm/pack, air dry weight: 250kg/pack

Bale size: 1400*840*2000mm/bale, quantity: 8 packs/bale, air dry weight: 2 tons/bale

We offer about 500g-1000g free sample of bamboo paper pulp for customer to test.

1. Paper production:

Bamboo pulp is utilized in the manufacture of paper products such as tissue paper, toilet paper, printing paper, and packaging materials. Its strong fibers and high cellulose content make it suitable for producing high-quality paper products.

2. Eco-friendly packaging:

Bamboo pulp-based materials are increasingly used in eco-friendly packaging solutions as an alternative to conventional plastics and paper-based packaging. Biodegradable and compostable packaging made from bamboo pulp helps reduce environmental impact and plastic waste.

3. Biodegradable products:

Bamboo pulp can be molded into various biodegradable products such as disposable tableware (plates, bowls, utensils), food packaging, and compostable containers. These products offer a sustainable alternative to single-use plastics and foam-based packaging materials.

4. Construction materials:

Bamboo pulp fibers can be incorporated into composite materials used in construction, such as bamboo fiberboard, panels, and insulation. These materials are lightweight, durable, and have good insulating properties, making them suitable for building and renovation projects.

Overall, the use of bamboo pulp extends across multiple industries where sustainability, versatility, and eco-friendliness are valued.

We can arrange the shipment for customer, by train or by sea. For international shipments, bamboo paper pulp can be transported by sea freight using cargo ships. Maritime shipping is suitable for large volumes of pulp and offers cost-effective transportation over long distances.

A 20’GP container has the capacity to carry 20 tons of bamboo pulp.

How to make bamboo paper pulp?

Making bamboo paper pulp involves several steps, and it’s quite similar to the process used for wood pulp, just with bamboo as the raw material. Here’s a basic overview:

- Harvesting: Bamboo stalks are harvested when they reach maturity. Harvesting must be done carefully to ensure sustainability and minimize damage to the environment.

- Preparation: The harvested bamboo stalks are cleaned and stripped of their outer layers to expose the inner fibers.

- Chipping: The bamboo stalks are then chipped or shredded into smaller pieces to facilitate the pulping process.

- Cooking: The bamboo chips are cooked in a chemical solution to break down the lignin and hemicellulose, which bind the fibers together. This process can involve either chemical pulping (using chemicals like sodium hydroxide and sodium sulfide) or mechanical pulping (using high-pressure steam).

- Fiber Separation: After cooking, the bamboo mixture is mechanically or chemically treated to separate the fibers from the rest of the bamboo material. This can involve washing, screening, and bleaching to produce a pulp with desired properties.

- Bleaching (optional): If a white pulp is desired, bleaching agents may be used to remove any remaining color from the pulp. This step is optional and depends on the desired end product.

- Washing and Drying: The pulp is washed to remove any remaining chemicals or impurities. Then, it is pressed and dried to form sheets or rolls of bamboo pulp.

- Finishing: The dried pulp may undergo further processing, such as cutting, refining, or blending with other materials, depending on its intended use.

It’s important to note that the specific process may vary depending on factors such as the type of bamboo, the desired quality of the pulp, and the available equipment and resources. Additionally, environmentally friendly and sustainable practices should be considered throughout the production process to minimize the ecological impact.

The advantages of bamboo paper pulp

Here are some key points highlighting the benefits of bamboo pulp:

1. Renewable Resource: Bamboo is one of the fastest-growing plants in the world, making it an abundant and highly renewable resource. It can be harvested sustainably without causing significant damage to the environment.

2. Versatility: Bamboo pulp can be used to produce a wide range of products, including paper, packaging materials and biodegradable products. Its versatility makes it a valuable raw material for various industries.

3. Strength and Durability: Bamboo fibers are known for their strength and durability, making bamboo pulp an excellent choice for products requiring resilience and longevity, such as paperboard, cardboard, and construction materials.

4. Biodegradability: Bamboo pulp is biodegradable and compostable, making it an eco-friendly alternative to synthetic materials that contribute to pollution and landfill waste. Products made from bamboo pulp can break down naturally at the end of their lifecycle, minimizing environmental impact.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

Jinrui All Rights Reserved.