- Jiangdong Str., Yiwu, Zhejiang, China.

- [email protected]

- +8617380463193

Bleached hardwood pulp chemical kraft pulp price

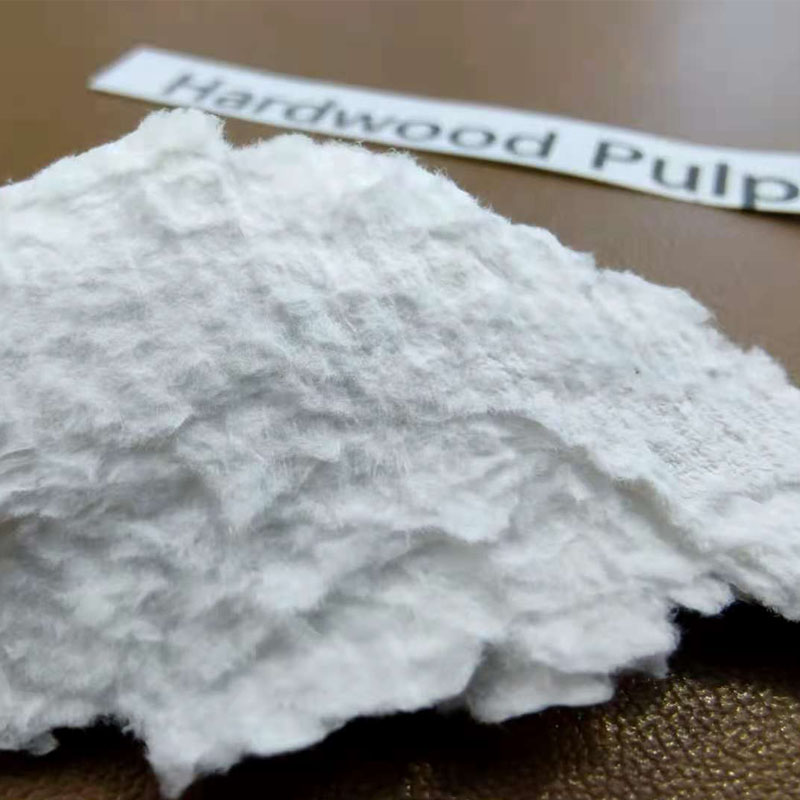

Hardwood pulp is a type of pulp produced from hardwood trees, which are typically deciduous trees such as oak, maple, birch, and beech. We use chemical pulping method to produce hard wood pulp.

The bleached hardwood pulp is commonly used in the production of paper, cardboard, and other cellulose-based products due to its strength, durability, and versatility.

The fiber length of hard wood pulp is shorten than softwood pulp. Hardwood pulp is often mixed with softwood pulp or bamboo pulp, derived from coniferous trees, to achieve desired properties in the final product.

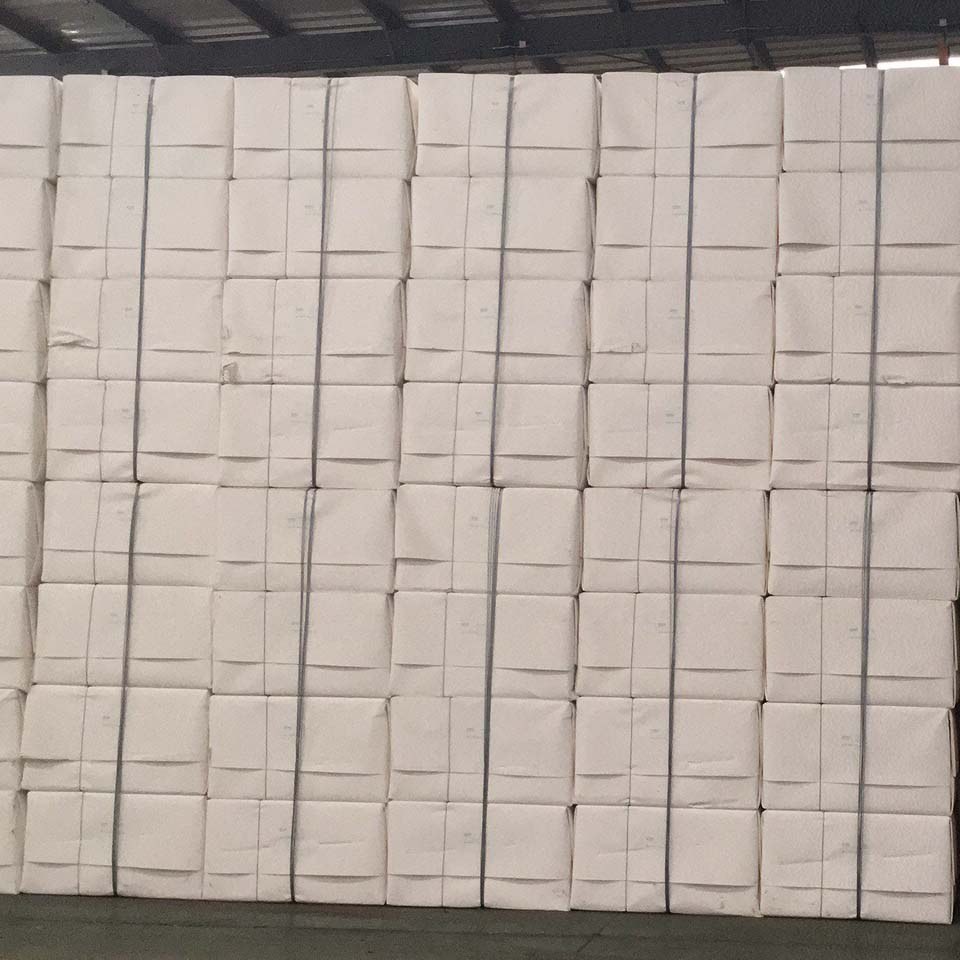

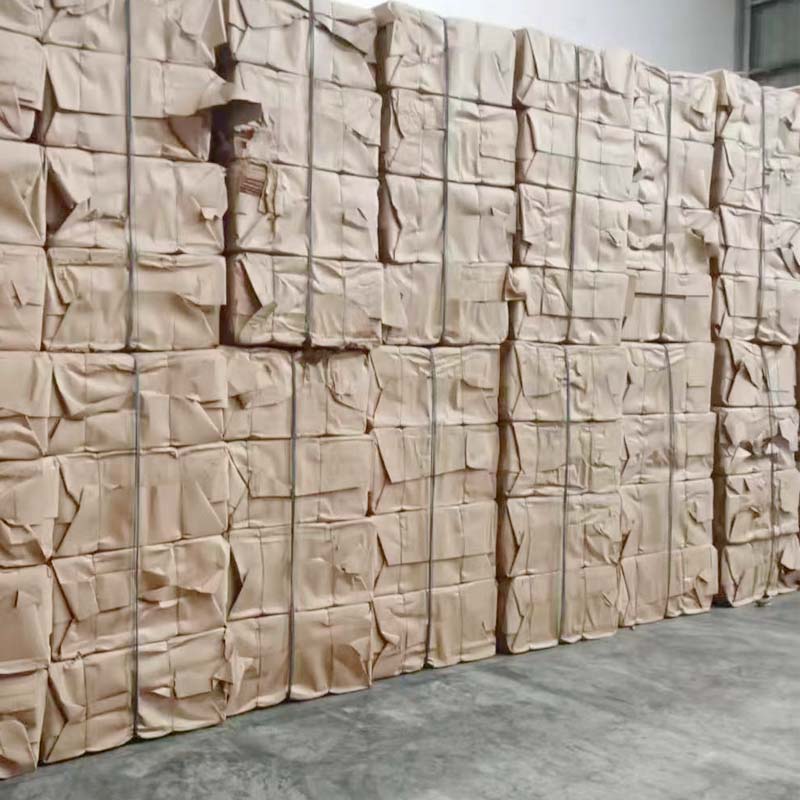

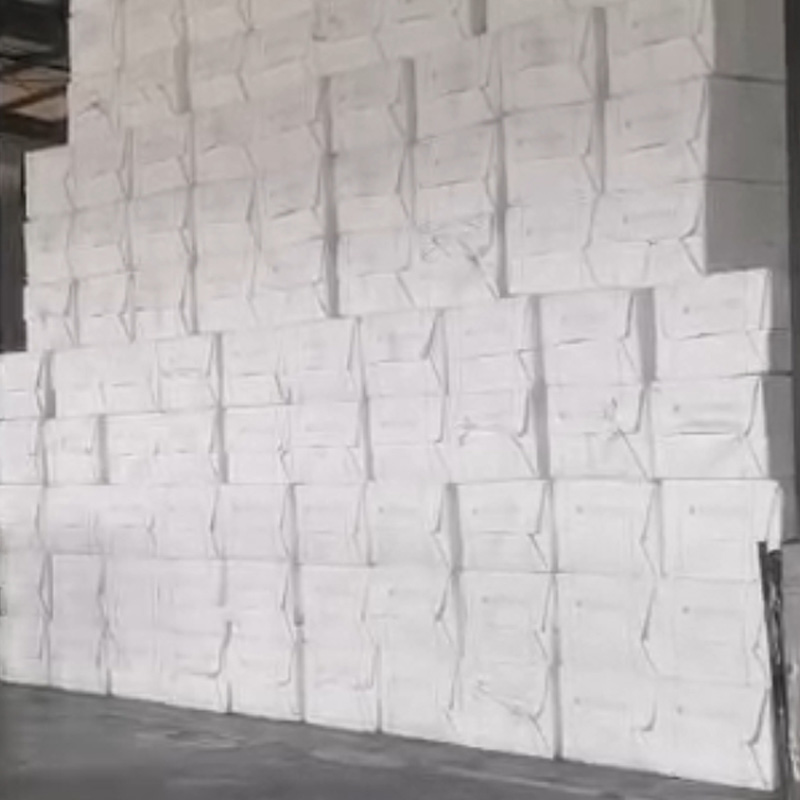

The hard wood pulp is in sheet form. It is packed in bale with iron wire.

Packing: 840*700*520mm/pack, 1400*840*1800mm/bale, around 1.98 tons/ bale.

Free sample: Available.

The technical data sheet of bleached hardwood pulp

Properties | Unit | Value |

Drainability | oSR | 45 |

Brightness | % | ≧85 |

Dirt count (0.3-1.0mm2) | mm2 /500g | ≦25 |

Dirt count (1.0-5.0mm2) | mm2 /500g | ≦15 |

Dirt count (>5.0mm2) | mm2 /500g | None |

Tensile index | N.m/g | ≧55 |

Burst Index | KPa·m2g | ≧3.5 |

Tear index | mN·m2g | ≧7 |

Viscosity | ml/g | ≧800 |

Moisture | % | ≦20 |

Ash content | % | ≦0.7 |

What are the products of hardwood pulp?

Hardwood pulp is used in the production of various products across different industries. Some common products made from hardwood kraft pulp include:

1. Paper:

– Printing and writing paper: Used for books, magazines, newspapers, office paper, etc.

– Specialty papers: Including tissue paper, facial tissues, napkins, and paper towels.

– Packaging paper: Used for packaging materials such as wrapping paper, gift bags, and some types of cardboard.

2. Cardboard and Cartonboard:

– Cardboard boxes: Used for packaging and shipping goods.

– Cartonboard: Used for packaging food and beverages, cosmetics, pharmaceuticals, and other consumer products.

3. Filters:

– Air filters: Used in HVAC systems and air purifiers.

– Liquid filters: Used in industrial processes, water purification systems, and consumer products like coffee filters.

4. Specialty Products:

– Cellulose acetate: Used in the production of cigarette filters, photographic film, and certain types of plastics.

– Non-woven fabrics: Used in medical supplies, hygiene products, and industrial applications.

– Chemical derivatives: Used in various industries for adhesives, coatings, and other applications.

These are just a few examples of the diverse range of products that can be manufactured using bleached hardwood kraft pulp as a raw material. The versatility and properties of hard wood pulp make it a valuable resource in many industries.

What is the difference between hardwood pulp and softwood pulp?

The main difference between hardwood pulp and softwood pulp lies in the type of trees from which they are derived and the characteristics of the fibers they produce:

1. Tree Source:

– Hardwood pulp is derived from deciduous trees, which are typically broad-leaved trees such as oak, maple, birch, and beech.

– Softwood pulp comes from coniferous trees, which are usually evergreen trees like pine, spruce, fir, and cedar.

2. Fiber Characteristics:

– Hardwood fibers tend to be shorter and have a more complex structure compared to softwood fibers. This complexity often results in hardwood pulp having a smoother surface texture.

– Softwood fibers are longer and have a simpler structure, which can contribute to higher strength and stiffness in the final product.

3. End Uses:

– Hardwood pulp is often used in applications where a smoother surface texture is desired, such as printing and writing papers, tissues, and some types of packaging.

– Softwood pulp is preferred in applications where strength and stiffness are critical, such as in the production of cardboard, boxboard, and other packaging materials.

4. Properties:

– Hardwood pulp tends to have higher bulk and opacity, making it suitable for products where these characteristics are important.

– Softwood pulp generally offers greater tensile strength and tear resistance, making it suitable for applications requiring durability and structural integrity.

Despite these differences, it’s common for manufacturers to blend hardwood and softwood pulps to achieve specific properties tailored to the intended use of the final product.

Welcome to contact with us to get the latest hardwood pulp price.

More products

Yiwu Jinrui is a professional supplier in the paper industry established in 2000, from paper raw materials bamboo pulp, bagasse pulp, wood pulp to various base papers.

Jinrui All Rights Reserved.